Ultrasonic waves are sound or vibration with a frequency too high to be heard by human ears, above approximately 20 kHz. Frequency is a measure of the number of repeated rounds per event in a given time interval. To calculate the frequency, someone set the interval, count the number of incident events, and dividing this count by long intervals. These results are given in hertz (Hz) where 1 Hz is the events that happen one time per second.

Ultrasonic waves are classified into two definitions are distinguished by the size and frequency of application (Mason, 1990) :

1. High frequency or diagnostic ultrasound (2-10 MHz).

2. Low frequency or power ultrasound (20-100 kHz).

Diagnostic ultrasound or low-amplitude waves are used to measure the velocity and wave absorption coefficient in the medium with a distance of 20-10 MHz. Usually used for medical applications, chemical analysis, and study the phenomenon of relaxation. While the power of ultrasound involves a high energy waves (low frequency), applied for cleaning, the unification of plastic, and to observe the influence of chemical reactivity.

When waves propagate into the liquid medium produces alternating pressure and expansion cycles. In addition to the expansion cycle, high-intensity ultrasonic waves cause small bubbles in the liquid. When the bubbles reach the volume that is not enough anymore to absorb the energy, the bubble burst, a phenomenon called "cavitation". High-intensity acoustic radiation which propagate through the medium led to some changes.

Effects and Mechanism of Ultrasonic Wave :

a. Cavitation

Cavitation is one of the effects of radiation due to ultrasonic waves in the fluid where terkompresinya terekspansi and gas bubbles in the liquid caused by ultrasonic wave radiation. If the ultrasonic waves radiated fluid, then fluid pressure will be increased (at first have a static pressure) when the wave amplitude has a positive and will decrease when the negative amplitude.

Due to this pressure change, then the bubbles of gas or vapor that usually exist in the fluid pressure will be compressed when the fluid rises and will terekspansi when the pressure drops. So long as there is an ultrasonic wave in the liquid, the gas bubble radius reaches a maximum value at the minimum at the time of expansion and compression. If the pressure amplitude ultrasonic waves big enough, then the bubble could burst. The outbreak of this bubble will menimbulan "shock waves" (shock waves). Because there is great pressure, then the shock waves that could damage ties on oil so that the weak will drop out.

b. Structural effects

When the fluid is placed under high intensity sound field, produced by the dynamic turbulence and shear stress on the structure, above all consistency. Perobekan cell can occur in several ways that relate closely to each other and expand Yeng disappeared or broken, there will be a very great motion near the bubble and the weak motion as far as some of the diameter of the circumstances. So part of the cell wall near the bubble will experience a large displacement relative to other parts of the cell wall. The resulting shear stress will easily tear the cell walls. Near cavity who disappeared there is also the type of turbulence with a great stir. The cell walls can be damaged by shear stress caused by this turbulence, so the compound on the inside of the cell will exit (Acherman et.al., 1988).

c. Heat Effects

Kuldiloke (2002) states that the acoustic energy absorption by the membranes and biomaterials, especially on the surface can increase the temperature. They stressed the heat balance equation to calculate the ultrasonic energy loss during propagation through the medium. They mentioned that the temperature changes should be absorbed by a solid under conditions of 0.1 °C for water and 1°C for air. These results have been verified through an experiment. Other studies claim local temperatures can rise up to 5000 ° K which is achieved in a few nanosecond in the sound field.

Advantages of Ultrasonic Method

Some advantages of this method is to simplify the process of ultrasonic extraction, mass transfer, distrupsi cells, increase the penetration effect. Research Mason et al., (1996) mentions in the process of extraction of compounds from fennel, hops, marigold, mint leaves and lemon can increase 20-40% of the results of ultrasonic extraction method compared to the usual extraction method. According to research, Cameron and Wang (2006) concerning the extraction of corn starch, corn starch yield states obtained from the ultrasonic process for about 2 minutes is about 55.2 to 67.8%, almost equal to the yield obtained from heating the water for 1 hour, namely 53 , 4%. Other studies on rice starch ekstaksi by Wang et al., (2004) mention the combination of 0.5% sodium sulfate with ultrasonic dedocyl rendement can increase up to 84.9% with low-residue protein.

Park et al., (2006) mentioned in the study of sorghum starch using sonication extraction efficiency is seen reduced protein content in it. It is influential on changes in protein content and color, among others, sonication time, concentration of solution, different types and concentrations of protein as well as settling agents sentrifugasinya speed.

The use of high frequency ultrasonic waves to improve monitoring of food products or processes to accelerate absorption. In industrial applications include texture, viscosity, and determination of concentration for egg products, meat, fruit, vegetables and dairy products. Kuldiloke (2002) mentions one of the benefits of the ultrasonic method is to accelerate the extraction process. With the use of ultrasonic extraction process of organic compounds in plants and seeds using organic solvents can take place more quickly. Mechanical effects of ultrasonic method is to increase the penetration of solvent into the cell material and to improve mass transfer. The cell walls of the material is broken down by ultrasonic vibrations so that the content in it can come out easily. This method has been used in the extraction process of sugar beet (Mason et al., 1999).

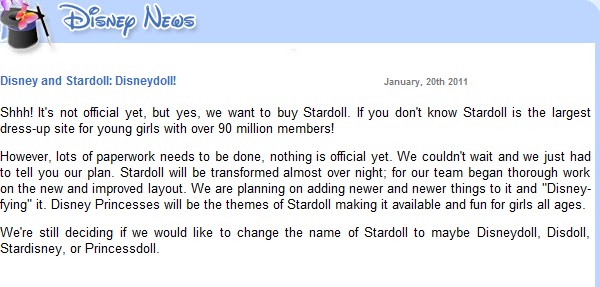

You gotta love SaltyDan, he never fails to get us all buzzing with his posts. In one of his recent posts on SMW, he stated how fed up he was with the newly crowned Miss Stardoll Word, Perlice2 and her non-stop greedy fame parade!

You gotta love SaltyDan, he never fails to get us all buzzing with his posts. In one of his recent posts on SMW, he stated how fed up he was with the newly crowned Miss Stardoll Word, Perlice2 and her non-stop greedy fame parade!